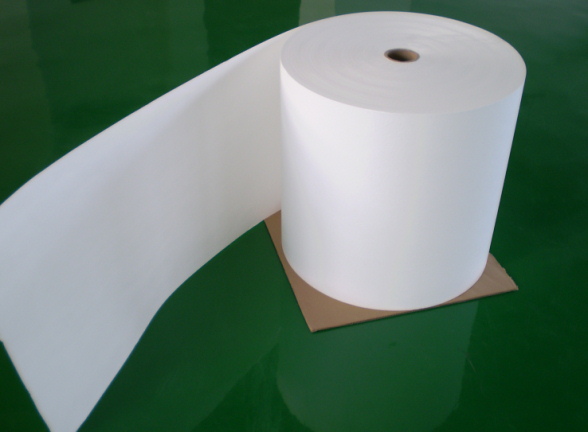

Non Woven Fabric

FilterFabrics is an eminent Filter Cloth Manufacturers in India offers premium quality Filter cloths

Filter Cloth

Clear Edge is pleased to give a broad scope of wet and dry filtration and screening items and fabrics.

With many years of experience discovering answers for clients, we have a profound learning of the numerous sorts of Filter media, screening and sieving items, and additionally involvement in assembling press materials, bas and belts to suit for all intents and purposes any procedure hardware.

This society of advancement is upheld by our in-house examination and nearby specialized backing.

We additionally offer full manufacture abilities to suit the requirements of our clients' individual Filter procedures and hardware — everything from sewing, edge medicines, substantial obligation crease welding and overwhelming obligation sewing to scissors insertion, eyelets, laser cutting and pack outline.

Fluidized Bed Dryer Bags

Clear Edge's Fluidized Bed Dryer Bags offer a tender answer for drying, measuring, agglomerating or splash covering of fragile substances in powder structure. The packs are regularly utilized as a part of procedure stages near the final item and have been demonstrated to streamline molecule catch and stream rate properties.

The precision and repeatability of our cutting frameworks guarantees this unpredictable pack outline is always fabricated to your accurate particulars.

Key components of our Fluidized Bed Dryer Bags include:

- Accuracy make-up

- Stringent quality control

- Prevalent drying

- Brilliant molecule catch

- Filter Press Fabrics

Clear Edge offers its clients a full scope of Filter Press Fabrics. These press materials can be produced with a customary neck or with licensed Coreflo® barrelneck innovation to fit numerous types and sizes of recessed chamber and layer Filter plates. The Coreflo® neck, being welded as opposed to sewed to the Filter fabric, results in unrivaled quality, dependability and execution.

This novel item likewise brags no seep through in line gaps, no filtration in the neck, enhanced center blow, fantastic fitting (no wrinkles) and better release.

Our Filter Press Fabrics give numerous advantages:

- No sudden diminishments in yield

- End of item misfortune

- Lessened differential weights

- Wrap over, caulked in styles

Fit all makes, including R&B, Edwards and Jones, Avery, Eimco, Diemme, Hoesch, Jord, JWI, Perin, Svedala, Netzsch and Schenk.

Drum, Pan Disk Covers

Accuracy woven Pan Filter Media are accessible from Clear Edge when you require steady seepage, cake development and washing to guarantee a clean, equally conveyed, dry Filter cake for release in alumina hydrate, phosphoric corrosive, titanium dioxide and different applications.

Our fabric and elastomeric circle covers have been idealized over numerous years to enhance washing, lower filtrate solids and lessen dampness content. Their high waste properties likewise offer our clients some assistance with achieving limit picks up in commonly substantial obligation applications.

Drum Filter Covers (move, blade, string and belt) require a strong, genuine following and stable media with quick cake development to advance cake thickness, lower cake dampness, lessen support and essentially decrease solids in filtrate.

Every one of our fabrics are created utilizing best in class specialized material and testing advances that empower us to coordinate our materials to your fancied filtration attributes.

The key components of our spreads are:

- Expanded tonnage and productivity

- Lower support costs

- Prevalent cake development and dryness

Politer Filter Fabric Tops Priority Among Synthetic Fabric Cloths

Polyester filter fabric with exact focusing encourage position

As a critical component of filter press, polyester filter material has been broadly acknowledged by an expanding number of producers and clients of filter press for its most grounded corrosive resistance and phenomenal resistance against hoisted temperature up to 302℉. Surface completions can be seared, calendered and warm set, each of which has its unique property and reason.

Why do you pick polyester filter fabric?

Fantastic blend properties, for example, smoothness, high rigidity, wear resistance and penetrability, enable it to be a powerful and well known filtration media. Different sorts of polyester yarns are given to fulfill specific applications. For instance, multifilament filter material reinforces its rigidity as well as guarantees great cake discharge. Diverse woven examples including plain, stain and twill, are composed with uncommon purposes.

For better comprehension of woven examples and yarn sorts, please click here. On the off chance that you are still confounded, get in touch with us without dither.

What are the upsides of polyester filter cloths?

- Elite resistance against most natural acids aside from high centralizations of nitric, sulfuric and carbolic acids;

- High elasticity;

- Extension: 20% - half;

- High working temperature: up to 302℉;

- Brilliant rough resistance;

- Great imperviousness to frail most oxidizing specialists;

- Great filter cake discharge;

- Long life range.

Where is polyester material utilized?

- Compound plant

- Compost plant

- Pharmaceutical

- Sugar

- Partition of oil and water

- Sustenance and drink

Comment:

- Not accessible for solid soluble bases at high temperature;

- Not suitable for some phenolic mixes;

- Not suitable for staying solids filtration.